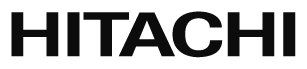

Hitachi Care & Green Service

Features

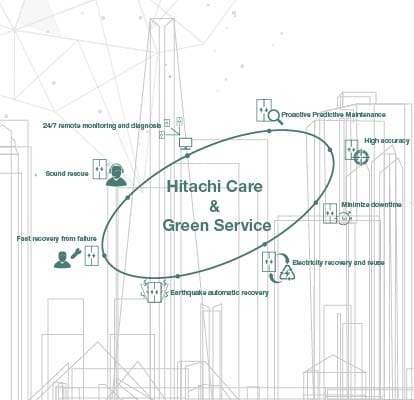

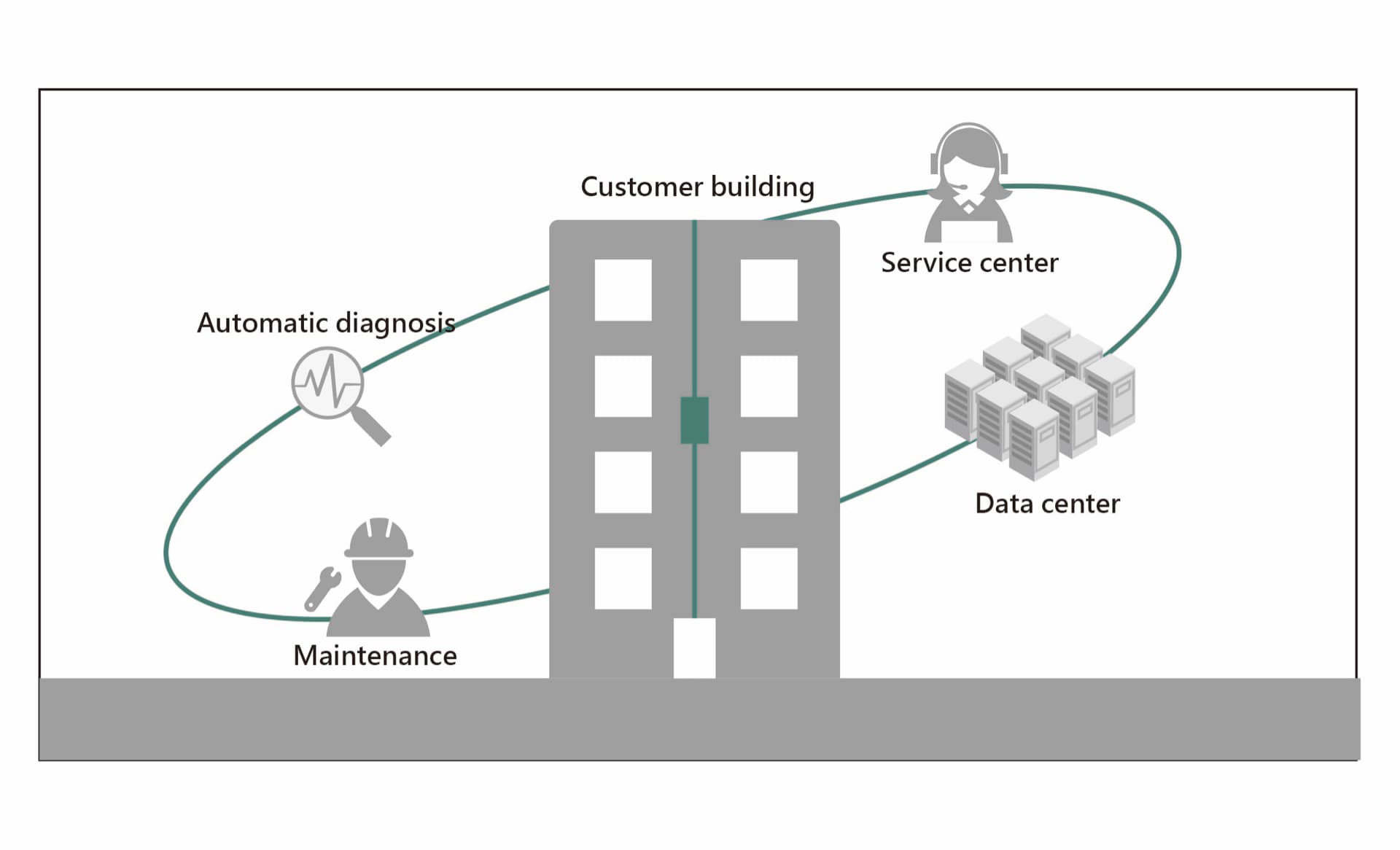

Point 1: 24/7 remote monitoring and diagnosis

- • Use the Internet of Things (IoT) and other digital technologies to remotely collect and monitor real-time elevator operation data and use the analysis of this data as the basis for predictive maintenance.

- • Perform inspections remotely 24 hours a day, 365 days a year, providing seamless, secure and reliable service quality.

Point 2: Proactive Predictive Maintenance

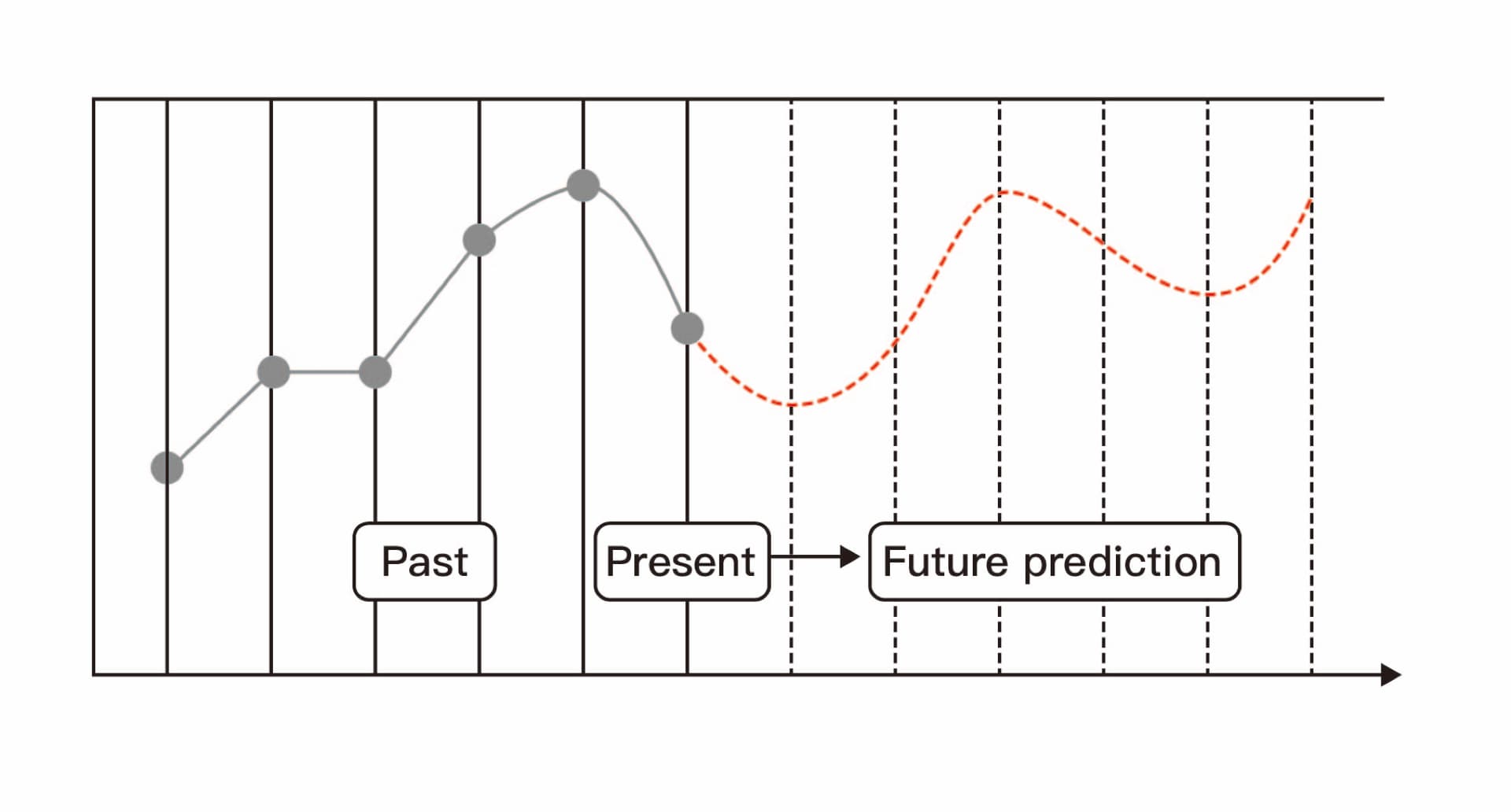

- • By comparing data from remote monitoring and diagnostics with data accumulated in the past, it is possible to proactively capture signs of failure and perform predictive maintenance.

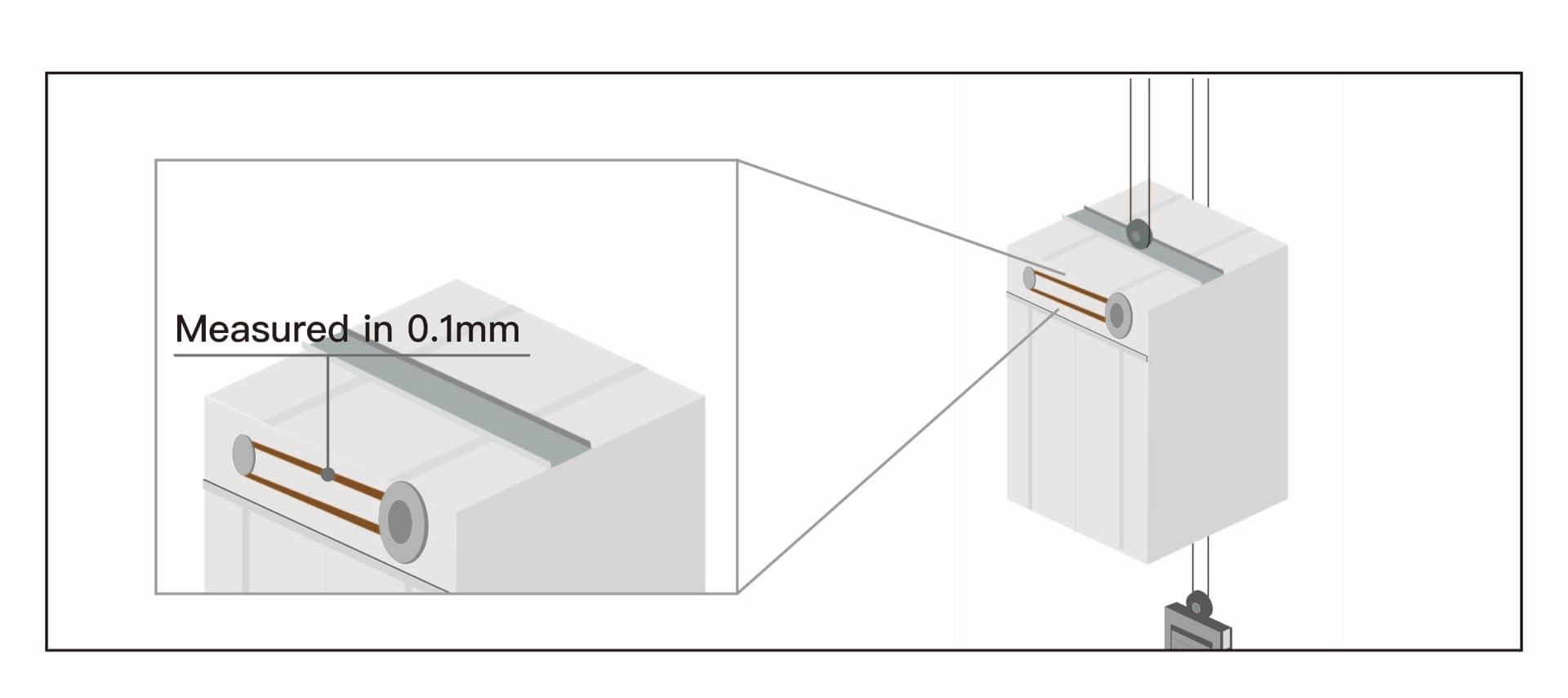

Point 3: Accuracy of early detection of anomalies

- • Detect important elevator equipment and safety devices in units of 0.1 mm with the accuracy of early detection of abnormalities.

Point 4: Prioritize customer convenience and minimize maintenance downtime

- • Remotely perform automatic diagnosis, measure and analyze various performance data at fixed times each month for preventive maintenance.

Point 5: In case of failure, the cause can be quickly identified and normal operation can be resumed

- • Remote failure cause analysis

Automatically collect and analyze operating data at the time of failure, quickly identify the cause, and contact field engineers to shorten repair time.

- • Remote glitch recovery

Automatically collect and analyze operating data at the time of failure to quickly find out the cause, and for minor failures that do not require replacement or adjustment of components, they can be recovered through remote control.

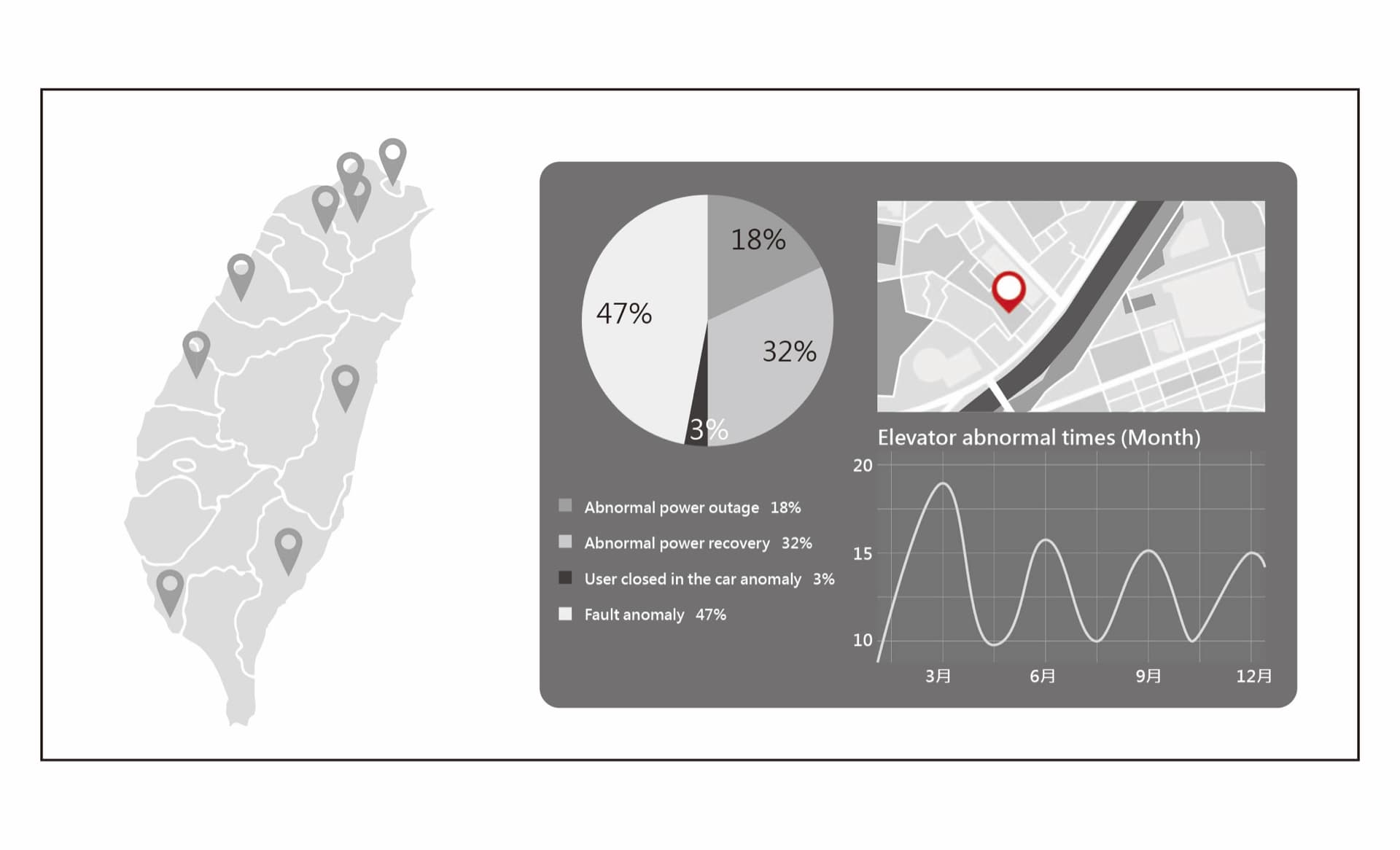

- • Provide monitoring system reports

Abnormal information and results of diagnostic tests will be reported to the customer in a clear and understandable manner.

Point 6: Sound rescue

- • In case the user is trapped in the car due to failure, the IoT Internet phone in the car can be used to maintain two-way contact with the service center.

- • We will urgently dispatch professional maintenance engineers to check the fault and restore the operation.

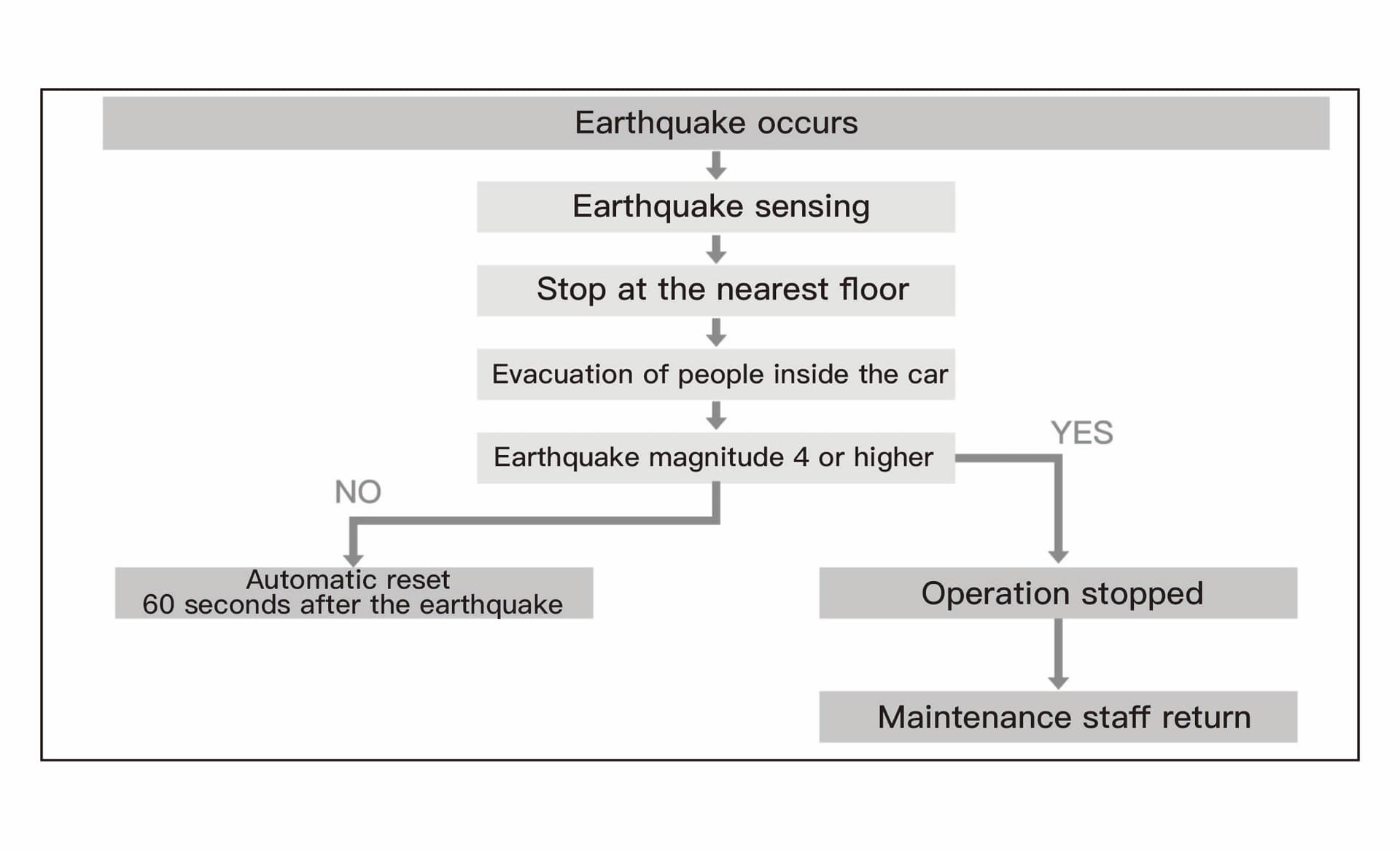

Point 7: Earthquake Automatic Recovery System

In the event of an earthquake with a magnitude below 4, the elevator will stop at the nearest floor to ensure safety. After the passengers are evacuated, the elevator will automatically resume normal operation 60 seconds after the earthquake, greatly shortening the recovery time for earthquake shutdown.

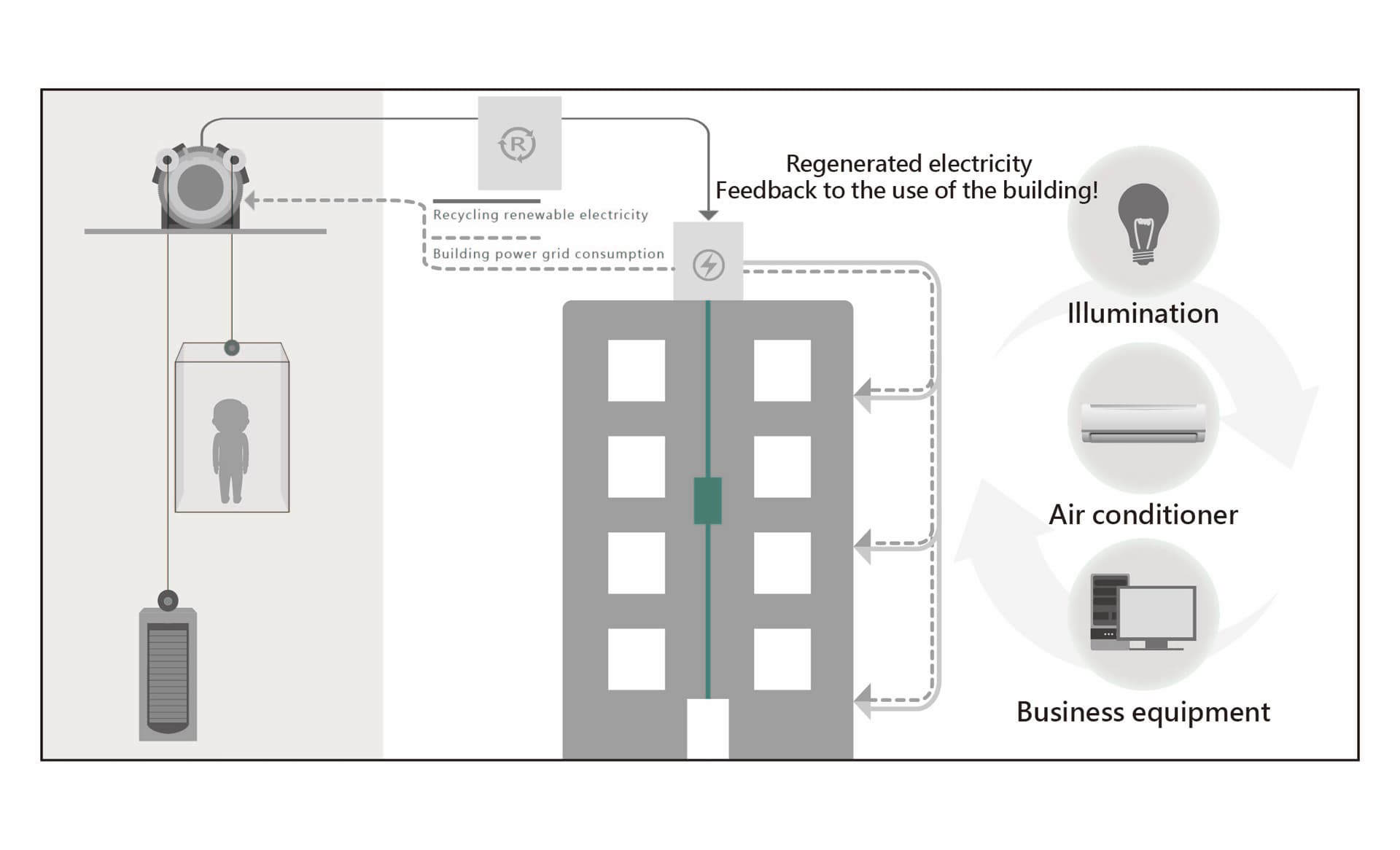

Point 8: The energy regenerator recovers electricity and reuse

- • The electric energy generated when the elevator is running will be consumed in the form of heat energy in the resistance box of the machine room, causing the temperature of the machine room to rise and reducing the service life of the products in the machine room.

- • The use of energy regenerators can recover the electric energy generated during elevator operation and feed it back to the power grid of the building for reuse in general daily electrical appliances, reducing the use of electric energy from Taipower.

- • The power saving rate varies according to different site conditions, and the average energy consumption can be saved by about 30%.

- • Obtained the EU VDI 4704 highest energy-saving level 5A certification.

Point 1: 24/7 remote monitoring and diagnosis

- • Use the Internet of Things (IoT) and other digital technologies to remotely collect and monitor real-time elevator operation data and use the analysis of this data as the basis for predictive maintenance.

- • Perform inspections remotely 24 hours a day, 365 days a year, providing seamless, secure and reliable service quality.

Point 2: Proactive Predictive Maintenance

- • By comparing data from remote monitoring and diagnostics with data accumulated in the past, it is possible to proactively capture signs of failure and perform predictive maintenance.

Point 3: Accuracy of early detection of anomalies

- • Detect important elevator equipment and safety devices in units of 0.1 mm with the accuracy of early detection of abnormalities.

Point 4: Prioritize customer convenience and minimize maintenance downtime

- • Remotely perform automatic diagnosis, measure and analyze various performance data at fixed times each month for preventive maintenance.

Point 5: In case of failure, the cause can be quickly identified and normal operation can be resumed

- • Remote failure cause analysis

Automatically collect and analyze operating data at the time of failure, quickly identify the cause, and contact field engineers to shorten repair time. - • Remote glitch recovery

Automatically collect and analyze operating data at the time of failure to quickly find out the cause, and for minor failures that do not require replacement or adjustment of components, they can be recovered through remote control. - • Provide monitoring system reports

Abnormal information and results of diagnostic tests will be reported to the customer in a clear and understandable manner.

Point 6: Sound rescue

- • In case the user is trapped in the car due to failure, the IoT Internet phone in the car can be used to maintain two-way contact with the service center.

- • We will urgently dispatch professional maintenance engineers to check the fault and restore the operation.

Point 7: Earthquake Automatic Recovery System

In the event of an earthquake with a magnitude below 4, the elevator will stop at the nearest floor to ensure safety. After the passengers are evacuated, the elevator will automatically resume normal operation 60 seconds after the earthquake, greatly shortening the recovery time for earthquake shutdown.

Point 8: The energy regenerator recovers electricity and reuse

- • The electric energy generated when the elevator is running will be consumed in the form of heat energy in the resistance box of the machine room, causing the temperature of the machine room to rise and reducing the service life of the products in the machine room.

- • The use of energy regenerators can recover the electric energy generated during elevator operation and feed it back to the power grid of the building for reuse in general daily electrical appliances, reducing the use of electric energy from Taipower.

- • The power saving rate varies according to different site conditions, and the average energy consumption can be saved by about 30%.

- • Obtained the EU VDI 4704 highest energy-saving level 5A certification.

Hitachi Care & Green Service

全方位服務